About

G’dday. My name’s Graham. It was about a decade ago when Lindsay Johnson and I got stuck in Haines midway through a sailing trip around Southeast Alaska. Rather than brave the freezing spray back to Ketchikan, we decided it was a good idea to purchase a cheap piece of second growth rainforest off the southernmost point of the Alaska road system.

It was November, I had overstayed my visa and was liable to be deported back to Canada as soon as the government figured out what I was up to. The ground was frozen so we reckoned the quickest way to get a roof over our heads was to suspend it from the trees and go from there. It was around this time of questionable decisions, unnecessarily dangerous wilderness trips and shotgun weddings we hatched the plan for Fairweather Ski Works.

We realized we needed jobs. “I kinda know how to build skis” I bragged. “We can totally compete with overseas manufacturing facilities that depend on unfair labor practices and don’t give half a shit about their waste streams” I added.

“Yeah, then we’ll stick it to their wall street sucking corporate overlords” added Lindsay.

“We’ve got some nice spruce trees, Ians got a boatbuilding shop, let’s get started”.

Fastforward ten years and we’re still living in the same treehouse and still building skis cause we still need jobs. To make things easier, we purchased a leaky old wooden fishing boat and started to produce offspring.

“We’re living the dream!” Lindsay exclaims over the roar of the Lynn Canal wind with baby Mira flopping in her front pack.

“America! Freedom!” I add with gusto as we post hole through the barely unsupportable crust dragging a sled full of ski cores on its side.

We arrive at the factory in Dalton City to find our underpaid immigrant laborer @ponkbart had been up all night bending edges. “You’re not done yet? Why I ought to replace you with another robot”

That’s right. I said robot

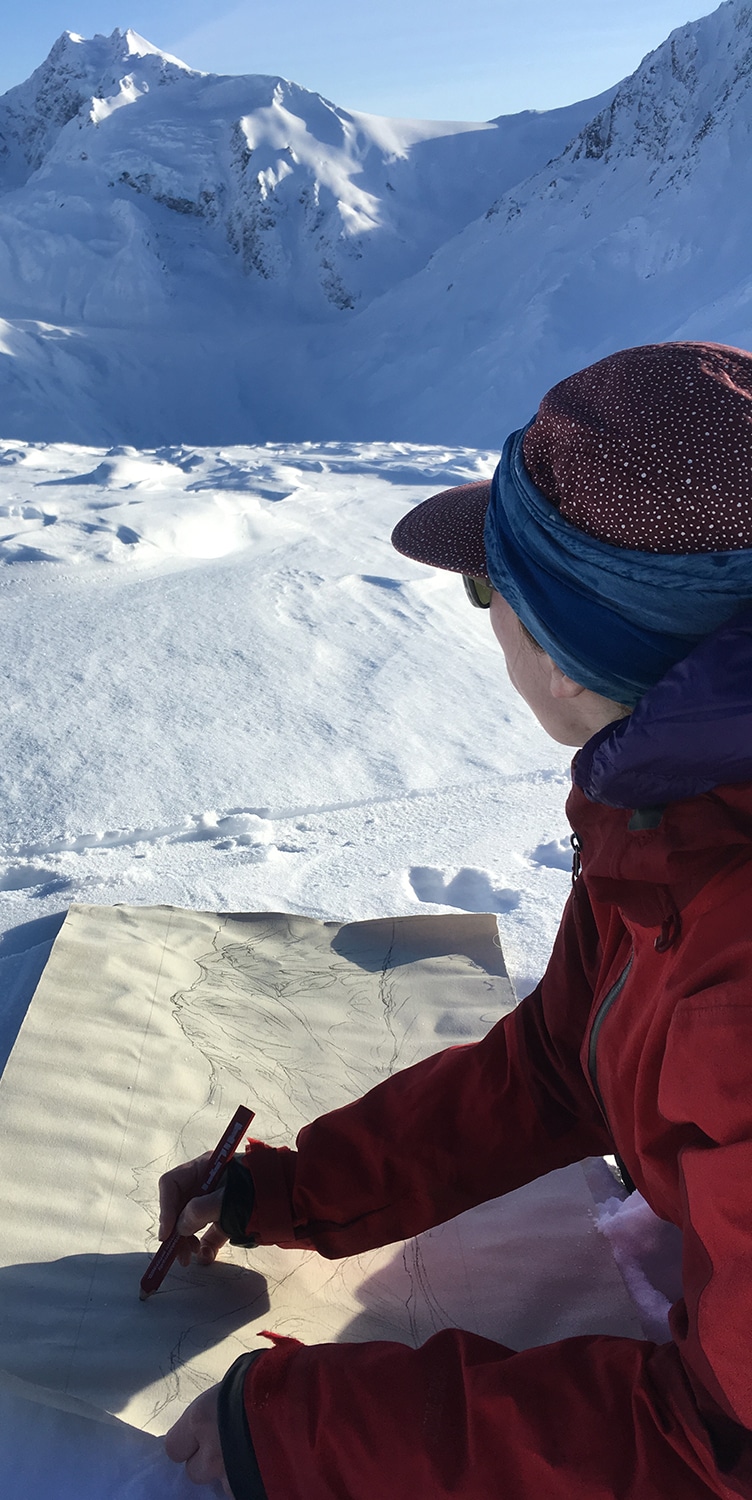

My buddy Eben and I built this CNC router from a kit full of nuts, belts, drives and pullies. He’s a real robot nerd, not to mention good ski bud. After college, he worked in industrial scale ski manufacturing and we jabbered about ski design for days while slogging across ice fields on spring trips throughout Alaska. One time, we almost fell down a giant hole in the glacier. We stepped back, then kept on going.

The idea behind the robot is that we can use it to cutout all the components that go into a ski or board, giving us a repeatable and customizable process to build a variety of shapes and sizes. Variety is the spice of life here, and we wouldn’t be doing this if there wasn’t something so stupidly fun about flying down a mountainside with a carefully shaped piece of tree strapped to our feet. One last thing about the robot: don’t listen to @ponkbart if he tells you the robots are taking all his jobs.

@ponkbart aka Bartek Piecuil

This guy’s the hired muscle at Fairweather. Perhaps most famous for almost getting dismembered by a brown bear while snowboarding, Bart has been with us for years. Originally from Poland, Bart moved to Detroit in his late 20’s where his experiences in the rave scene earned him the position as the official DJ of the Fairweather shop.

After a thorough brain washing and indoctrination from watching too many Absinthe snowboard movies, at 30, he up and moved to Haines Alaska to learn to ride. Bart is one of the most enthusiastic and motivated shredders in a place not know for its beginner terrain. Tagging along with some experienced locals such as Haines Avalanche center forecaster and fellow Fairweather shop hand Jeff Moskowitz, Bart figured it out pretty quickly. In a funny twist to the story, the Absinthe crew has been known on occasion to call him for snow reports.

Bart is also notably one of our most valuable product testers. Feared by most outdoor gear manufacutrers because of his ability to destroy equipment, Bartek can find a design flaw in a prototype pretty quick as he straight lines into a tight patch of trees.

Oh yeah, the trees!

Believe it or not, most modern production skis are still built with a wood core. The path of least resistance as a ski company would be for us to order up mass produced pre-made, rough shaped core blanks like most other companies and we would certainly be time and money ahead.

Instead, we take a hard left detour and harvest our wood components locally. Despite the fact that we are surrounded by wilderness that is jam packed with perfect ski building wood, the logistics of pulling it off has proven to be pretty daunting.

The accessibility of wood and availability of loggers and sawyers in a small town are certainly variables to juggle. We are lucky to have people like Chad @ Stump Huggers and Sean Dogg Brownell @ Alaska Heliskiing who work with us to choose sustainable sources for premium lumber, even clearing for ski runs and turning them into shred sticks. This approach fulfills our desire to manage our business responsibly and makes us advocates for a small scale timber industry and local sustainable jobs.

Much of the industrial scale logging in our region now takes the form of round log exports to Asia where they are milled and manufactured into low cost products, only to be shipped back across the ocean (possibly even as ski cores) and sold back to us at a lower price than is humanly possible around here. Large scale logging some of the last remaining old growth forest on the planet is not only short sighted, but it also threatens some of our favorite ski terrain, along with the wildlife and salmon that indigenous people here have depended on for millennia.

Why does this ski company keep talking about salmon? I just want to shred!

For us, fishing and skiing are the seasonal tides which dictate our lives. As soon as the snow begins to melt off the hills, we start work preparing our 50 year old wooden troller, Sika, for another summer on the ocean.

While completely dissimilar in some ways, the techniques used in boat building and ski building share some commonality. First, one of the most common builders tools, the level, is completely useless. Might as well throw the straight edge overboard too because the curves that cut through water molecules in their liquid or frozen state are as much refined by the eye as they are by computer calculations. We owe some of the fine craftsmanship in our skis to techniques learned under the wing of a couple local shipwrights who helped us keep our boat floating.

Right around the time the sun seemingly ceases to set, the salmon start to trickle in. We pack up the boat, the kid and the dog and spend the remainder of the daylight hours fishing for salmon. Trolling –a hook & line fishery– is about the least efficient way to commercially catch fish. Just like hiking for your turns, we like it because it results in the highest quality product, but also the sport, adventure, and the art.

We catch 'em one at a time

Fresh King Salmon!

Sikas guts exposed during a recent rebuild

Trolling the outer coast of Southeast Alaska

Art.

Ski building, at least the way we do it, is art as much as anything.

Perhaps its the long winter nights or the crisp clear days that inspire so many Alaskans to pick up a paintbrush. Whatever it is, we have stumbled into an incredible talent pool of artists with this job.

We certainly derive some type of satisfaction when we pull a fresh top sheet design out of the mold. Blending this artwork into the curves and lines of the skis and boards takes it to another dimension.

We build products that are essentially paintbrushes for your feet, whether an untracked powder slope or blank section of a map is your thing, we want our trees to take you there!